The Breathable Strength of PU Composite Fabric in Modern Applications

Posted by Admin

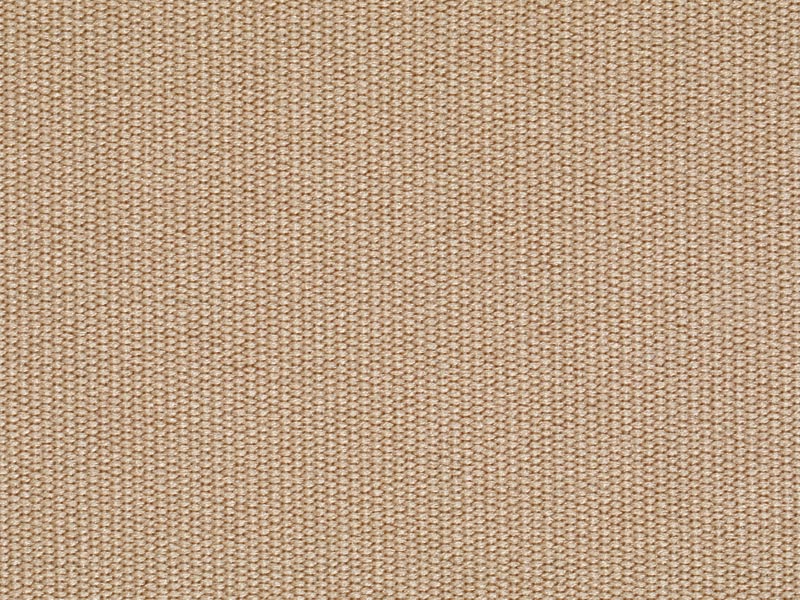

In the evolving landscape of textile innovation, PU Composite Fabric stands out as a versatile and functional material meeting the needs of various industries. Known for its unique balance of performance and comfort, PU Composite Fabric is especially valued for its breathability, a characteristic often overlooked in technical fabrics. As users demand more comfort from their clothing and gear, PU Composite Fabric continues to gain attention for offering both durability and air permeability.

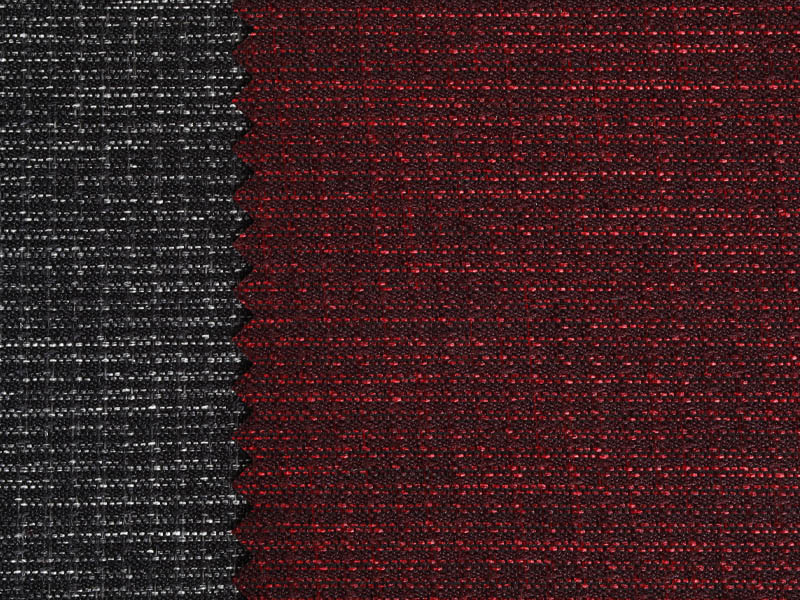

At its core, PU Composite Fabric is a multi-layered material, created by bonding a polyurethane (PU) coating to a base fabric, such as polyester or nylon. This fusion results in a fabric that inherits the resilience of the base layer while enhancing it with the protective and flexible nature of polyurethane. While PU Composite Fabric is widely recognized for its water resistance and windproof qualities, its ability to allow air and moisture vapor to pass through is what sets it apart in comfort-focused applications.

Breathability in PU Composite Fabric is achieved through specific engineering methods. Micro-porous structures or semi-permeable PU membranes allow air exchange without compromising the fabric’s barrier properties. This design ensures that while rain or wind cannot penetrate, sweat and body heat can escape. In environments where temperature regulation and comfort are crucial, such as in outdoor sportswear, protective uniforms, and activewear—PU Composite Fabric proves to be an ideal solution.

Consider a hiker climbing a damp mountain trail. The outer shell of their jacket, made from PU Composite Fabric, protects them from light rain and wind gusts. At the same time, it prevents the uncomfortable buildup of heat and moisture inside. This dual action enhances endurance and comfort. It’s no surprise that PU Composite Fabric is increasingly chosen by outdoor apparel brands seeking to deliver high-performing gear.

Beyond clothing, PU Composite Fabric finds a place in everyday products such as backpacks, seat covers, upholstery, and even medical equipment. In each of these, breathability translates to long-term usability. For example, in medical mattresses or wheelchair cushions, PU Composite Fabric allows airflow that helps reduce heat and moisture buildup, contributing to skin health and user well-being.

From a production standpoint, manufacturers value PU Composite Fabric for its consistency and adaptability. It can be customized in thickness, elasticity, and finish to suit a range of requirements, without losing its breathable qualities. This flexibility has made PU Composite Fabric a go-to material in fields where performance, hygiene, and comfort intersect.

Another notable feature is that PU Composite Fabric maintains its breathable properties over time. Unlike coated fabrics that may degrade or delaminate, quality PU Composite Fabric retains its structure and airflow, even with repeated use and exposure to the elements. This durability ensures that the material delivers long-lasting performance, making it cost-effective over the product's lifespan.

In conclusion, PU Composite Fabric bridges the gap between technical functionality and user comfort. Its breathability is more than just a feature—it’s a defining advantage. As industries continue to innovate, the demand for breathable, adaptable materials will only grow. PU Composite Fabric, with its unique blend of protection and ventilation, is well-positioned to meet that need, whether in high-altitude adventure gear or everyday comfort solutions.

\

English

English Français

Français Español

Español عربى

عربى Tiếng Việt

Tiếng Việt