How PU composite fabrics achieve aesthetic advancements in color, texture, and durability?

Posted by Admin

The conversation surrounding PU Composite Fabric has traditionally centered on performance: waterproofing, breathability, and durability. Yet, a significant shift is underway as manufacturers and brands recognize that aesthetics are equally crucial for market success. Consumers and industries demand materials that not only perform exceptionally but also look sophisticated and maintain their visual appeal over time. This evolving focus is driving exciting innovations specifically within the realms of color, texture, gloss, and, critically, colorfastness in PU composite fabric.

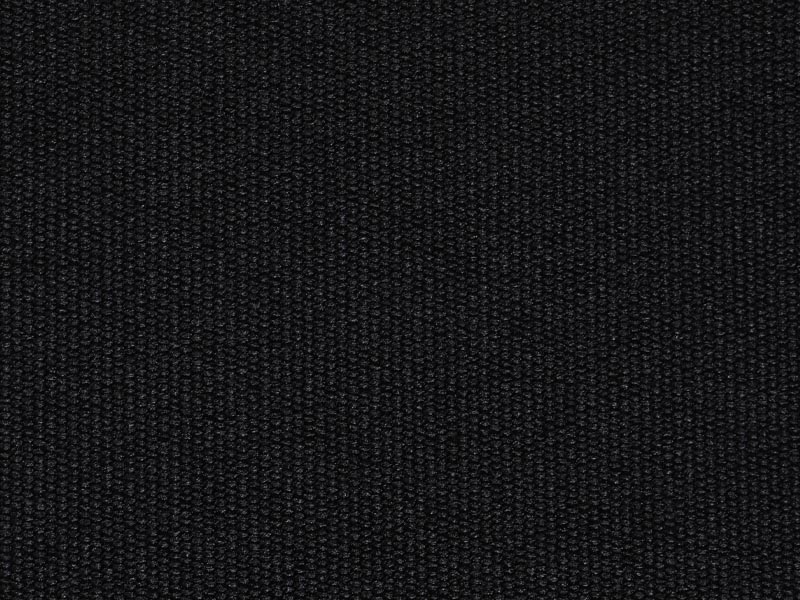

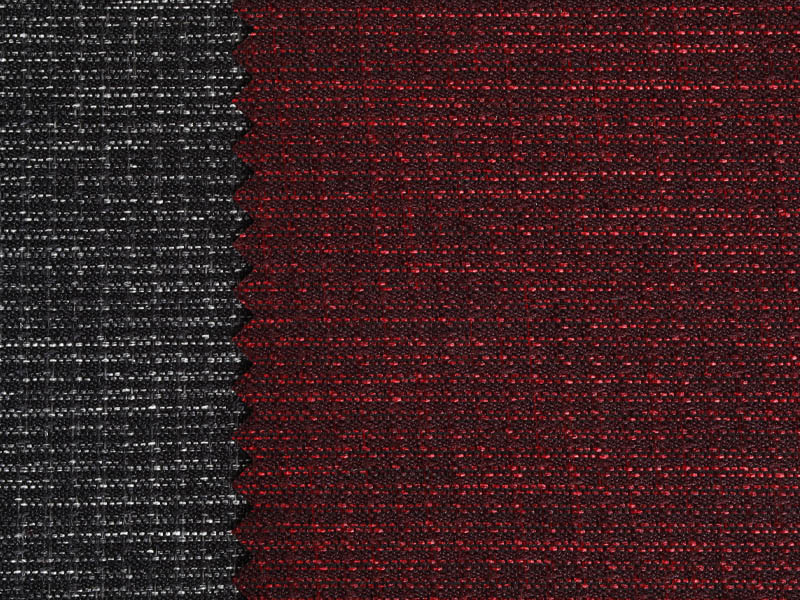

Unleashing Color Potential and Gloss Precision

Gone are the limitations of basic hues. Advanced pigmenting and coating technologies allow contemporary PU Composite Fabric to achieve an spectrum of vibrant, deep, and nuanced colors. Whether targeting the high-fashion sector seeking bold statements or the contract furniture market requiring specific corporate palettes, the color capabilities of modern PU Composite Fabric are a major selling point. Equally important is the precise control over surface gloss. Manufacturers can now consistently produce PU Composite Fabric ranging from ultra-matte finishes – prized for a luxurious, understated elegance and reduced glare—to high-gloss surfaces that deliver a sleek, contemporary, and easily cleanable aesthetic. This level of control over color saturation and gloss level allows designers unparalleled freedom. "We're no longer constrained by the material's limitations when specifying color and sheen for high-visibility applications," notes a senior designer at a outdoor furniture brand. "The PU Composite Fabric options now match our creative vision precisely.""

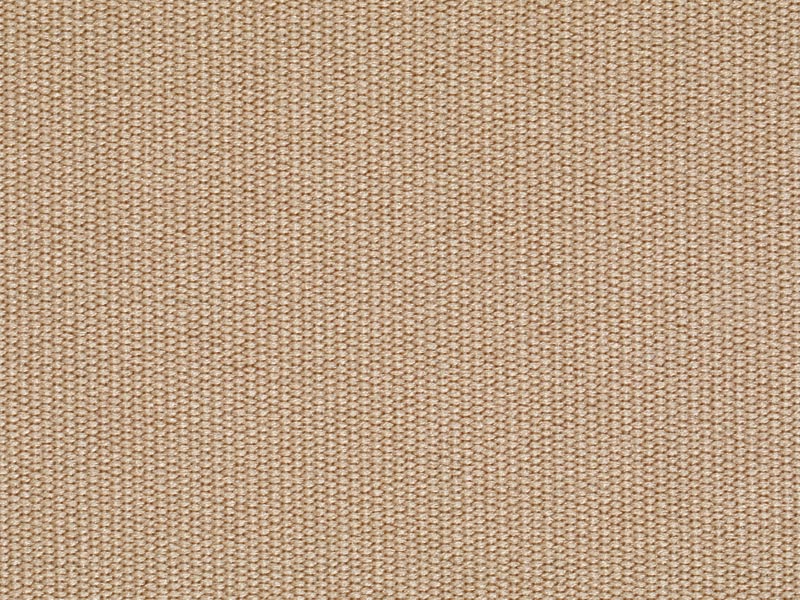

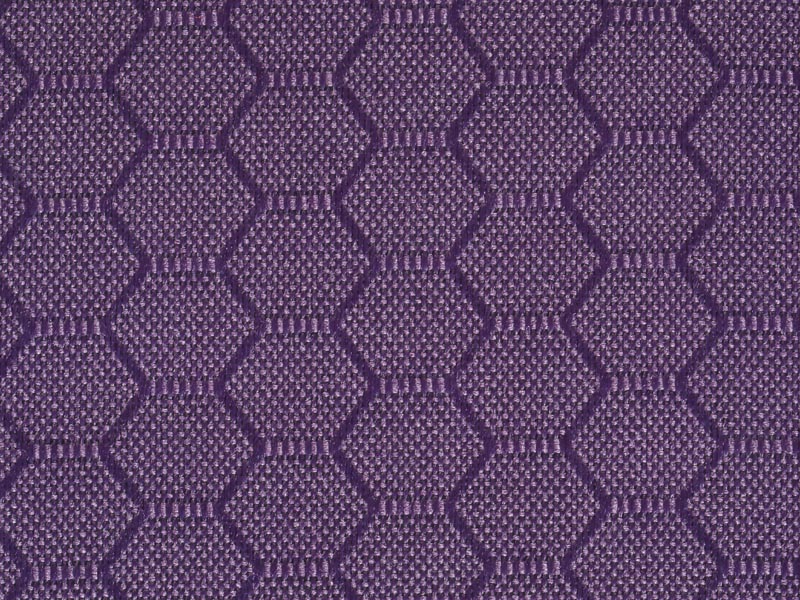

Texture: Elevating the Sensory Experience

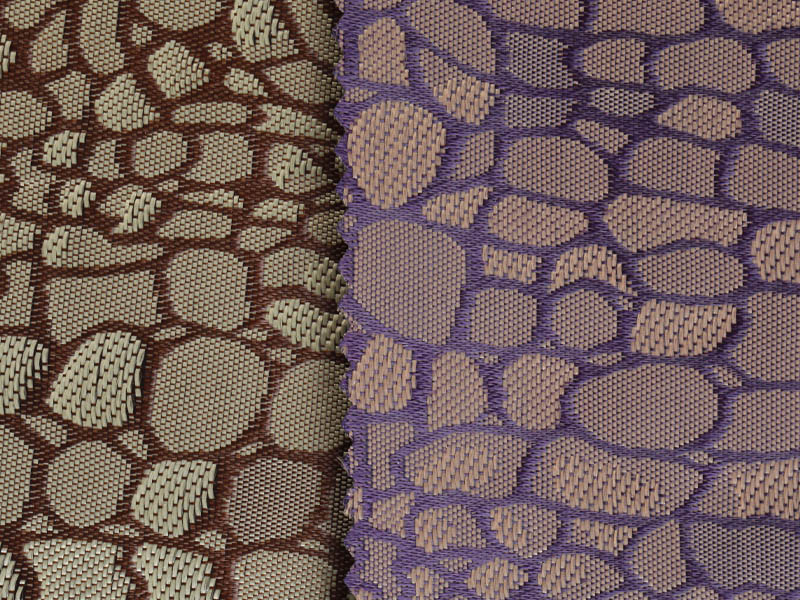

The tactile dimension of PU Composite Fabric is undergoing a revolution. Sophisticated embossing and finishing techniques enable the creation of remarkably realistic and diverse surface textures. Consumers can find PU Composite Fabric mimicking the fine grain of premium leather, the intricate weave of natural fabrics like linen or canvas, or even unique geometric and abstract patterns. This textural enhancement isn't merely visual; it significantly impacts the user's tactile experience and perception of quality. A PU Composite Fabric with a subtle pebbled texture feels more substantial and luxurious than a perfectly smooth counterpart. In automotive interiors, for instance, textured PU Composite Fabric provides enhanced grip and a premium feel on seats and consoles. The ability to engineer specific textures directly into the PU Composite Fabric surface expands its application potential far beyond purely functional uses.

The Paramount Challenge: Ensuring Lasting Beauty Through Colorfastness

Brilliant colors and exquisite textures mean little if they fade, migrate, or degrade quickly. Colorfastness is the cornerstone of long-term aesthetic value in PU Composite Fabric. This encompasses resistance to several key aggressors:

Lightfastness (UV Resistance): Preventing fading or color shift due to prolonged sun exposure is critical for outdoor furniture, awnings, automotive interiors, and apparel. Premium PU Composite Fabric incorporates advanced UV stabilizers within the polymer layers and coatings to shield pigments effectively.

Rub Fastness (Crocking): Preventing color transfer from the PU Composite Fabric surface onto other materials (like clothing) during abrasion is essential, especially for upholstery, bags, and shoes. Enhanced binder systems and surface treatments improve this key performance indicator.

Wash Fastness: For apparel and items requiring cleaning, the PU Composite Fabric must retain its color integrity through multiple wash cycles without bleeding or fading. Robust dyeing/pigmenting techniques and protective topcoats are vital.

Resistance to Chemicals & Perspiration: Ensuring colors remain true when exposed to cleaning agents, body oils, or sweat is crucial for automotive, marine, and performance apparel applications of PU Composite Fabric.

Manufacturers are investing heavily in proprietary coating chemistries, advanced dyeing methods, and integrated stabilizer packages specifically designed to bolster the colorfastness of PU Composite Fabric. Rigorous testing against international standards (like AATCC or ISO methods) for light, rub, and wash fastness is now standard practice to guarantee performance claims. "A fabric can look stunning initially, but its true value is proven over years of use," states a technical manager at a major PU Composite Fabric producer. " Our R&D is intensely focused on ensuring our materials not only meet but exceed colorfastness expectations across all relevant stressors. The longevity of the aesthetic is non-negotiable for premium PU composite fabric."

Market Impact and Future Directions

This heightened focus on aesthetics is broadening the appeal of PU Composite Fabric across diverse sectors. Fashion brands leverage its color vibrancy and texture for statement pieces; furniture makers appreciate the combination of durability and sophisticated looks; the automotive industry values the premium feel and long-lasting color. As sustainability pressures grow, innovations are also emerging in eco-friendly colorants and finishes that don't compromise on fastness properties for PU Composite Fabric.

The trajectory is clear: the future of PU Composite Fabric lies not just in its functional prowess, but in its ability to deliver enduring, customizable beauty. The synergy of vibrant color palettes, precisely engineered textures and gloss levels, underpinned by uncompromising colorfastness, is transforming PU Composite Fabric from a purely utilitarian material into a versatile and aesthetically driven design solution. The next generation of PU Composite Fabric will be judged as much by its visual and tactile appeal over its lifespan as by its technical performance.

English

English Français

Français Español

Español عربى

عربى Tiếng Việt

Tiếng Việt