How Modern Tent Fabric Technology is Reshaping Outdoor Adventures?

Posted by Admin

From alpine expeditions to weekend campgrounds, the unsung hero protecting explorers from nature's whims is the very skin of their shelter: Tent Fabric. This engineered material has undergone a revolution, moving far beyond simple canvas to become a sophisticated system balancing weight, durability, weather resistance, and environmental responsibility. The evolution of Tent Fabric is not merely a matter of convenience; it fundamentally alters how humans interact with the wilderness, enabling safer, lighter, and more sustainable journeys.

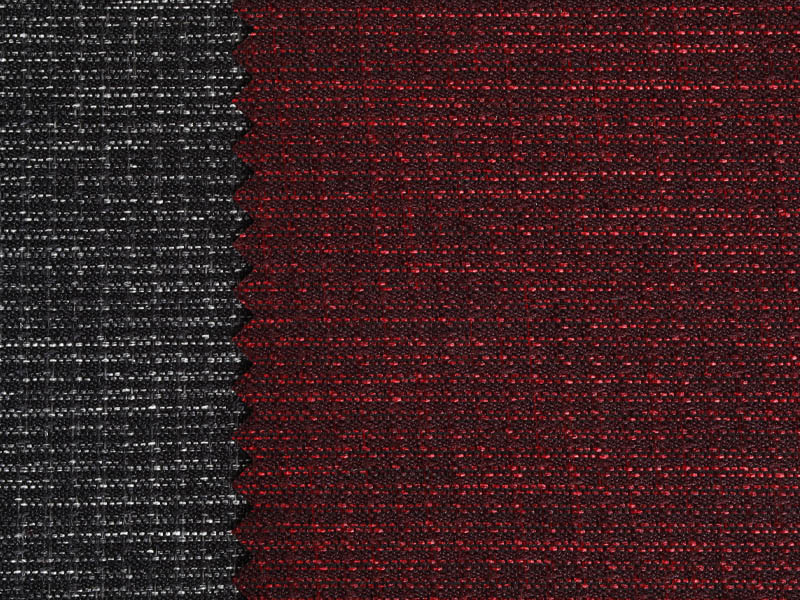

Historically, shelters relied on heavy natural fibers like cotton canvas. While durable, these materials absorbed water, became burdensome when wet, and offered limited insulation. The advent of synthetic polymers marked a turning point. Nylon and polyester emerged as foundational materials for modern Tent Fabric, prized for their inherent strength-to-weight ratio, inherent water resistance, and quick-drying properties. The development of coatings and laminates further transformed these base materials into formidable barriers. Today’s high-performance Tent Fabric is typically a composite structure, often featuring a durable outer layer treated with water-repellent coatings (DWR), a critical waterproof barrier (like polyurethane or silicone laminate), and sometimes a protective inner layer.

The primary function of any Tent Fabric system is to create a reliable, weatherproof sanctuary. This demands exceptional hydrostatic head ratings to withstand prolonged downpours without leaking, coupled with robust tear strength to resist wind gusts and accidental abrasion. Silicone treatments, applied to nylon (silnylon) or polyester, significantly enhance durability and water resistance while minimizing weight gain – a crucial factor for backpackers scrutinizing every ounce. This advanced Tent Fabric technology ensures the interior remains dry even during extended storms, providing essential comfort and safety.

Beyond basic waterproofing, managing internal climate is vital. Condensation, caused by warm, moist air from occupants meeting the cooler Tent Fabric walls, can be a major nuisance. Modern designs address this through breathability. While no Tent Fabric is truly 'breathable' like a jacket fabric under heavy rain pressure, strategic ventilation via mesh panels and carefully engineered single-wall fabrics using microporous coatings or laminates help mitigate moisture buildup. The choice of Tent Fabric directly impacts interior humidity levels and occupant comfort.

Ultraviolet radiation poses a significant threat to both the longevity of the shelter and its occupants. Prolonged exposure degrades fibers, causing fading and weakening the Tent Fabric. High-quality Tent Fabric incorporates UV inhibitors and stabilizers directly into the yarns and coatings, significantly extending the lifespan of the shelter, especially critical for mountaineering or desert expeditions. This protective aspect of the Tent Fabric is essential for ensuring long-term reliability in harsh sunlight.

The pursuit of lighter loads drives constant innovation in Tent Fabric. Ultra-high-tenacity nylons and polyesters, combined with incredibly thin yet durable waterproof laminates like Dyneema Composite Fabric (DCF), push the boundaries of minimal weight without sacrificing essential protection. While DCF represents a premium option, advancements in ripstop nylon and polyester Tent Fabric technologies continuously improve the weight-to-strength ratio available to a broader market. Selecting the Tent Fabric involves balancing weight savings against durability needs and budget constraints.

Sustainability is increasingly woven into the fabric of the outdoor industry, and Tent Fabric is no exception. Manufacturers are actively exploring solutions to reduce their environmental footprint. This includes incorporating recycled content (like recycled polyester from plastic bottles) into the base Tent Fabric, developing more durable coatings to extend product lifespans, researching PFC-free waterproofing treatments that are less environmentally persistent, and implementing take-back programs for end-of-life tents to recover materials. The future of responsible Tent Fabric hinges on closing the loop through improved recyclability and circular design principles.

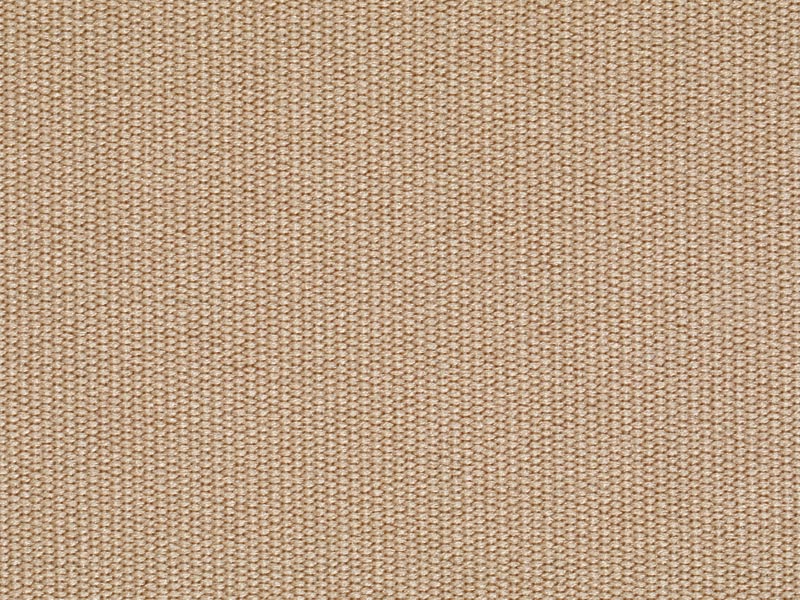

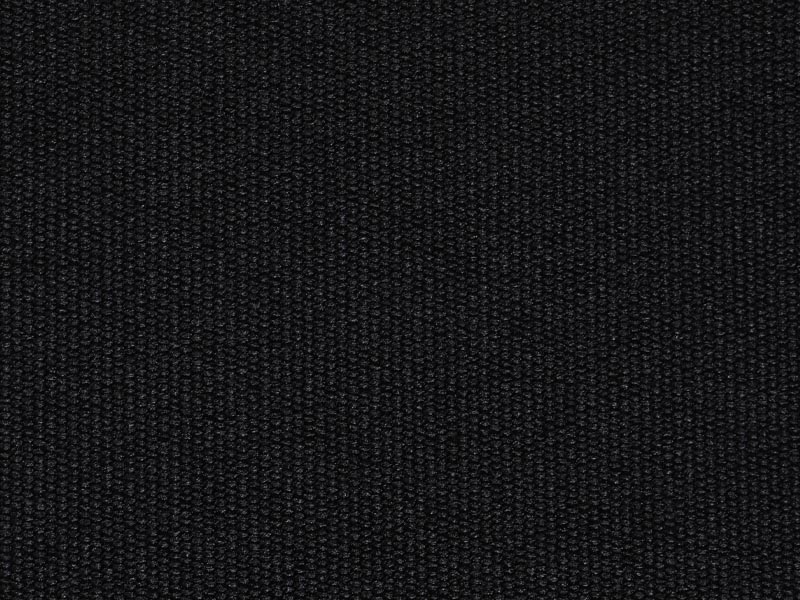

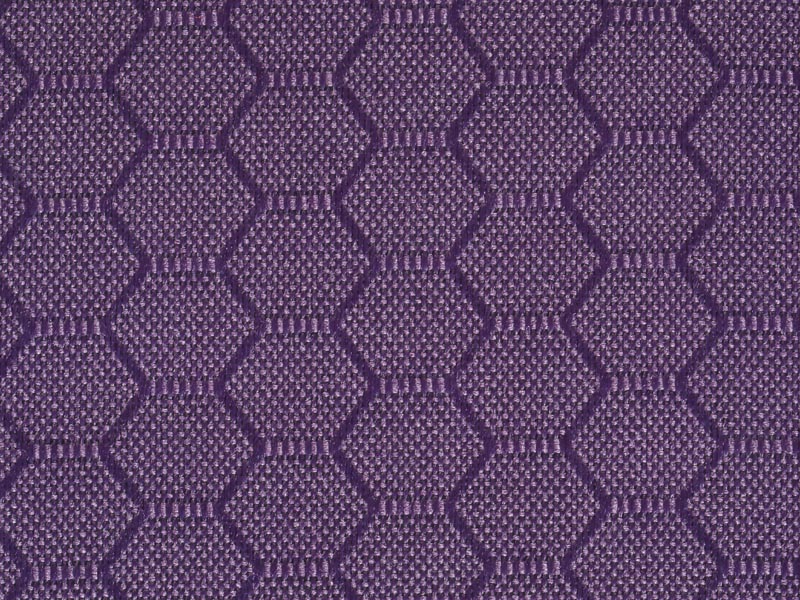

The feel and functionality of Tent Fabric also influence the user experience. Fabrics with a softer hand feel are generally preferred for sleeping compartments, while heavier-duty, more abrasion-resistant Tent Fabric is chosen for high-wear areas like floors. The tactile quality of the Tent Fabric, along with its acoustic properties (dampening rain noise), contributes significantly to the perceived comfort and quality of the shelter.

"Tent Fabric is the cornerstone of shelter performance," explains Dr. Lena Sharma, a materials engineer specializing in outdoor gear. "It's a complex interplay of chemistry and physics. Every advancement – a more eco-friendly coating, a stronger fiber, a lighter laminate – translates directly to how people experience the outdoors. Reliability starts with the right Tent Fabric."

Looking ahead, the development of Tent Fabric promises further integration of smart technologies and enhanced sustainability. Research explores self-healing coatings for minor punctures, dynamic fabrics that adjust permeability based on temperature or humidity, and bio-based polymers offering performance rivaling synthetics with a lower environmental impact. The ongoing refinement of Tent Fabric will continue to redefine the boundaries of lightweight exploration and comfort in the wild.

In essence, the humble Tent Fabric is a marvel of modern material science. It is the critical barrier that transforms a simple structure into a reliable home away from home, shielding adventurers from storms, cold, and UV rays. As technology progresses and sustainability imperatives grow stronger, the evolution of Tent Fabric will remain central to enabling safer, lighter, and more responsible connections with the natural world. This engineered skin is truly the unseen shield empowering exploration.

English

English Français

Français Español

Español عربى

عربى Tiếng Việt

Tiếng Việt